Is your cassette deck struggling to maintain consistent playback speed or experiencing frequent tape slips? It may be time for a TEAC W-800R drive belts replacement. Over years of use, the elastic belts within the cassette mechanism can wear out, stretch, or even snap, causing audio playback issues. In this guide, we’ll walk you through the entire replacement process, helping you extend the life of your beloved TEAC W-800R.

Why Replace the Drive Belts on a TEAC W-800R?

-

Improved Playback Quality

Worn belts can lead to inconsistent speed, fluttering audio, or a complete inability to play or rewind tapes. Replacing them ensures stable, accurate playback. -

Extended Equipment Lifespan

Fresh belts reduce mechanical strain on the motor and gears, potentially prolonging the overall life of your TEAC W-800R. -

Smoother Operation

A worn belt often translates into jerky fast-forward or rewind functionality. New belts enable the deck to respond more smoothly. -

Reduced Wear on Other Components

When belts are in optimal condition, they’re less likely to place undue stress on motors, pulleys, and gears.

Tools & Materials Needed

-

Replacement Belts: Ensure you have the correct size and type for the W-800R model.

-

Phillips Screwdrivers: Both small and medium sizes are typically required.

-

Tweezers or Needle-Nose Pliers: For handling delicate internal components.

-

Isopropyl Alcohol & Cotton Swabs: For cleaning pulleys and surfaces before installing new belts.

-

Soft Cloth or Microfiber Towel: Prevents scratches on the deck’s exterior and internal parts.

-

User Manual (If Available): Helpful for identifying specific parts and screw locations.

Step-by-Step Guide to TEAC W-800R Drive Belts Replacement

-

Power Off and Unplug

-

Always disconnect your cassette deck from any power source before beginning repairs to prevent shock or damage.

-

-

Remove the Outer Cover

-

Using your Phillips screwdriver, carefully remove the screws on the deck’s outer casing. Keep screws organized so you can easily reassemble later.

-

-

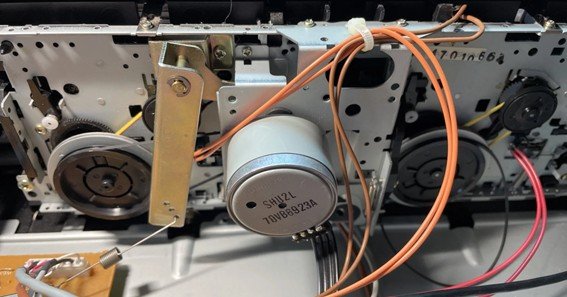

Access the Mechanism

-

Gently lift the cover to expose the internal components. Look for the motor, pulleys, and existing drive belts.

-

Depending on your unit’s layout, you may have to remove additional screws or plastic panels that secure the tape transport mechanism.

-

-

Assess the Old Belts

-

Examine the condition of the current belts. They may appear brittle, stretched, or partially broken. Make note of their exact routing and orientation.

-

-

Remove the Worn Belts

-

Use tweezers or needle-nose pliers to carefully slip each belt off its pulleys. Watch out for any cracked or degraded rubber fragments left behind.

-

-

Clean Contact Surfaces

-

Moisten a cotton swab with isopropyl alcohol. Gently wipe down the pulleys and motor spindle. This removes any residue that could affect traction.

-

-

Install the New Belts

-

Compare the new belts to the old ones to ensure proper sizing.

-

Slide each belt into position around its respective pulleys, replicating the original routing you observed or photographed before removal.

-

-

Check Tension & Alignment

-

Verify the belts are centered on their pulleys and not twisted. Spin the motor shaft or manually move the mechanism to ensure smooth rotation.

-

-

Reassemble the Deck

-

Replace any panels or brackets removed earlier, then securely fasten the outer cover.

-

Double-check that you haven’t dislodged any wires or connectors during the process.

-

-

Test the Deck

-

Power on the TEAC W-800R, load a cassette, and test play, rewind, and fast-forward functions. Listen for stable speed and watch for smooth operation.

FAQ

-

Q: Where can I find replacement belts for my TEAC W-800R?

A: Many online electronics parts suppliers specialize in audio equipment belts. You can also check auction sites or dedicated vintage audio forums. Ensure the belts match the W-800R’s model specifications. -

Q: How often should I replace the drive belts?

A: It varies based on usage and storage conditions. Many users replace belts every 5–10 years. If you notice any speed inconsistencies or tape slipping, it’s worth checking the belts. -

Q: Do I need any special technical skills for this?

A: Basic mechanical and electronics knowledge helps, but careful beginners can successfully replace belts by following detailed instructions and exercising patience. -

Q: Is it possible to use generic belts if I can’t find the exact type?

A: While some generic belts may work if they match dimensions (length, thickness, width), always try to use belts specifically recommended for the TEAC W-800R to ensure ideal performance. -

Q: What if I’m not comfortable opening the unit myself?

A: Consider seeking a professional audio repair service or a local electronics technician. They’ll have the expertise and tools to handle the replacement safely.Stay tuned to learn more about cansecos-weekly-ad